Situation Description and Objective

This

exercise is based on Example 4.2 (Worker and Production Planning at SureStep)

in the textbook. Most companies need to determine a production schedule in

order to meet the demand of their customers. We will use Excel Solver to plan a production schedule that will minimize total

costs given certain constraints. During the next 4 months, SureStep Company

wants to meet on time the following demands for pairs of shoes:

|

Month |

Pairs

of shoes |

|

1 |

3000 |

|

2 |

5000 |

|

3 |

2000 |

|

4 |

1000 |

Note that

this is the certainty assumption that the company faces. Normally, we do not

know how much to produce in each month given the limited amount of resources

needed to produce the shoes. But, here, for the sake of simplicity, we set the

target to those 4 months values. The following are the input variables to begin

with:

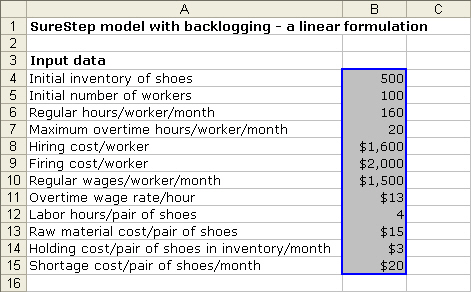

- At the beginning of month 1,

the company has 500 pairs of shoes and 100 workers on hand.

- A worker is paid $1500 per

month

- Each worker can work up to

160 hours per month before he/she receives overtime

- Overtime for each worker is

limited to 20 hours per month and the rate paid per hour of overtime is

$13

- It takes 4 hours of labor and

$15 of raw materials to produce a pair of shoes

- At the beginning of each

month, workers can be hired or fired

- Each hired worker costs

$1600, and each fired worker costs $2000

- If there’s any shoe left in

inventory at the end of the month, holding cost of $3 per pair is incurred

- If the company fails to meet

a unit of demand, a penalty cost of $15 is incurred during each month for

which a shortage occurs

Figure

1

The

solution requires that we keep track of each month’s beginning inventory,

ending inventory, production and all costs

The goal of this spreadsheet is to

determine the optimal production schedule and labor policy

We will

look at some of the variables that

will determine the final output.

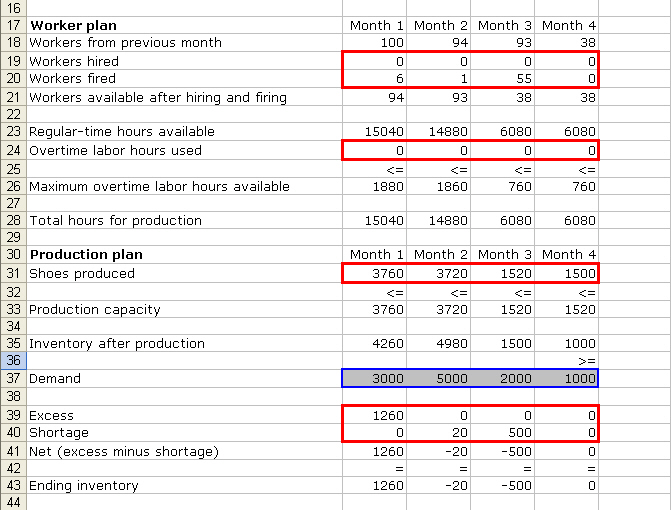

We know

that the company has 100 workers at the beginning of month 1. If they decided

to hire 0 worker and fire 6, then the number of workers available after firing

and hiring = 94. The # of worker to hire and the # of

workers to fire at the beginning of each month are the decision variables. Each

worker has 160 hours per month. Hence, the “regular total hours available” = 94

x 160 = 15040 hours. This does not include the number of overtime labor hours

the company decides to use. Now, we have 96 workers available to produce shoes.

Each worker has overtime limit of 20 hours. The maximum overtime hours

available = 96 x 20 = 1920. Does it mean that the company will use the maximum

overtime hours available? The overtime labor hours

used is the decision variable and it varies from month to month.

Remember that the company wants to use the combination of variables that best

maximize the total profit. Let’s say, the company uses 0 overtime hours. Total

hours used for production = regular total hours available + overtime labor

hours used (15040 = 15040 + 0)

Next, we

determine the “production capacity” by dividing the “number of hours used for

production” by the “number of hours used to produce a pair of shoes.” For

example, if there is 15040 total hours for production and it takes 4 labor

hours to produce a pair of shoes, then the production capacity = 15040/4 = 3760

We know

that the production capacity in month 1 = 3760. Suppose the company decides to

produce 3760 shoes (The decision to produce x number of shoes is the decision

variable). Then “inventory after production” is simply the addition of

last month’s ending inventory (500) to this month’s # of shoes produced (3760).

The demand for the first month is 3000. Ending Inventory is calculated by

subtracting “demand” by “Inventory after production.” If the result is

negative, then it means the company fails to meet the desired demand. A

shortage cost = $15 per unit. If “demand” is less than “inventory after

production,” the company has some shoes left in the inventory that is not sold.

The holding cost = $3 per pair of shoes. This example shows us that the company

has 1260 ending inventory. The cost of holding excess inventory = 1260 x $3 =

$3780.

The

company wants to make sure that by the end of month 4, demand is met. This

means that Ending Inventory in month 4 cannot be negative (the company will not

incur shortage cost). If there’s excess inventory, the company will incur

holding cost. If the ending inventory = 0, the company does not incur any cost.

This is consistent with the idea of minimizing cost.

Figure

2

Click

here to get the spreadsheet

Variables & Attributes

|

Variables |

How Measured |

Related to |

|

# of

workers available after hiring and firing |

Integer |

# of

workers from previous month & hiring of new workers and firing of

existing workers |

|

Regular-time

hours available |

Hours |

# of

workers after hiring and firing & each worker’s hours per month before

receiving overtime |

|

Maximum

overtime labor hours available |

Hours |

# of

workers after hiring and firing & each worker’s 20 overtime hours per

month |

|

Total

hours for production |

Hours |

Regular-time

hours available & Overtime labor hours used |

|

Production

capacity |

Number

of pairs of shoes (cannot be fraction) |

Total

hours for production & # of labor hours required to produce a pair of

shoes |

|

Inventory

after production |

Number

of pairs of shoes (cannot be fraction) |

Prior

month’s ending inventory & # of shoes produced in the current month |

|

Ending

inventory |

Number

of pairs of shoes (cannot be fraction) |

Inventory

after production & # of units demanded |

|

Decision Variables |

How Measured |

Subject to constraints: |

|

# of

workers hired |

Integer |

Value

has to be integer (can not be fraction) |

|

# of

workers fired |

Integer |

Value

has to be integer (can not be fraction) |

|

Overtime

labor hours used |

Hours |

Maximum overtime labor hours available |

|

Shoes

produced |

Number

of pairs of shoes (cannot be fraction) |

Production

capacity |

|

Excess

shoes |

Number

of pairs of shoes (cannot be fraction) |

|

|

Shortage

shoes |

Number

of pairs of shoes (cannot be fraction) |

|

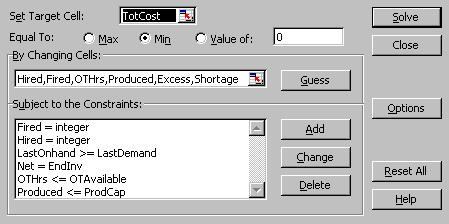

Mathematical Model Formulation

The objective of this linear model is to minimize total costs. Therefore, “total costs” has to

be set as a target cell. We choose

to minimize total costs by adjusting the number of workers hired (B19:E19), the

number of workers fired (B20:E20), the overtime labor hours used (B24:E24) and

the number of shoes to produce (B31:E31). These are the decision variables. The values in these changing cells can be

changed to optimize the objective.

Figure

3

Constraints must be set as follows:

The

number of workers hired & fired must be set as integer (cannot be fraction).

The inventory after production in month 4 must be bigger or equal to the number

of shoes demanded in that month. Overtime labor hours used in each month cannot

exceed the maximum overtime labor hours available. The number of shoes produced

in each month cannot exceed the full production capacity. Net excess minus

shortage equals Ending Inventory. If there’s excess of 10 pairs of shoes, then

there’s no shortage. If there’s excess of -10 pairs of shoes, then shortage =

10 pairs.

The values

in the changing cells cannot be negative.

Development of Spreadsheet Model

We have

already shown the steps to develop the spreadsheet model. The first step is to

enter the values given in the exercise in the input cells (shown in Figure 1). Next,

we input trial values in the changing cells. The formulas for other variables

must also be set. For example, Production capacity in month 1 (B33) = Total

hours for production (B28) x number of labor hours used to produce a pair of

shoes (B12).

Then we

invoke Excel Solver and set it up as shown in Figure 3 (subject to

Constraints). Since this model is a linear model, we go to Options menu and

check both “Assume Linear Model” and “Assume Non-Negative.”

We’re now

ready to tell Solver to find the optimum solution. Clicking Solve button will

do all the jobs in no time.

The final

step is to run sensitivity analysis and see the impact of the increase/decrease

in input variable on the output.

Results

We found

that in order to minimize total costs, we will have to fire some workers in

month 1-3 and hire none in each of the 4 months. Overtime labor hours will not

be used. The company will have to use full production capacity. Finally, we see

that the company will have to incur holding cost in month 1 and shortage cost in

month 2 & 3. There is no shortage or holding cost in the last month because

the company has to meet the demand. The minimum total costs solver found is

$690,180. Let’s do what-if analysis. Is there any way to decrease the total

costs by changing any of the input variable? We will change the unit shortage

cost (increment of $5) to determine if there is a better alternative for

SureStep.

Sensitivity of

shortages in the first three months and total cost to unit shortage cost

|

Unit

shortage cost |

Shortage1 |

Shortage2 |

Shortage3 |

TotalCost |

|

|

$B$40 |

$C$40 |

$D$40 |

$F$53 |

|

$0 |

0 |

2,280

|

1,640

|

$621,740

|

|

$5 |

0 |

2,220

|

1,580

|

$640,920

|

|

$10 |

0 |

2,220

|

1,580

|

$659,920

|

|

$15 |

0 |

2,220

|

1,580

|

$678,920

|

|

$20 |

0 |

20 |

500 |

$690,180

|

|

$25 |

0 |

20 |

20 |

$692,780

|

|

$30 |

0 |

0 |

0 |

$692,820

|

|

$35 |

0 |

0 |

0 |

$692,820

|

As we

see, when the unit shortage cost is below $20, SureStep is willing to incur

large shortages – at significantly lower total cost. However, shortages become

much less attractive when the unit shortage cost increases, and no shortages

are incurred at all when this unit cost is above $25.

DSS Guidelines & Limitation

This model proves to be simple but useful in assisting labor and production planning. It is essentially every manufacturing company’s problem. The model could be enhanced by including other variables which may prove to be relevant in addressing company’s issues. All in all, this spreadsheet model is a linear model that helps solve the optimal value of an output given certain constraints and formulas that follow it. We have proven that we can use Excel Solver to solve an interesting optimization problem such as this one. We know that the target cell in this model is a linear function of the changing cells. The left-hand and right-hand sides of each constraint are linear functions of the changing cells. When we use the functions =IF, =ABS, =MAX, =MIN which depends on any of the models changing cells, then the model becomes nonlinear. This in turn become an optimization problem for which Excel Solver is ill suited to find optimal solutions. Fortunately, genetic algorithm technique, as discussed in the textbook, can be used as a superior tool to find the optimal solution. The problem becomes more challenging if there’s uncertainty factor in it, such as a demand which is normally distributed with certain monthly mean and standard deviation.